CO2 RECOVERY

Apsley Farms recovers the CO2 produced in its fermentation for use within the food industry. We provide a sustainable alternative to traditional means of manufacturing this important product.

Cleaning Biogas and Extracting CO2

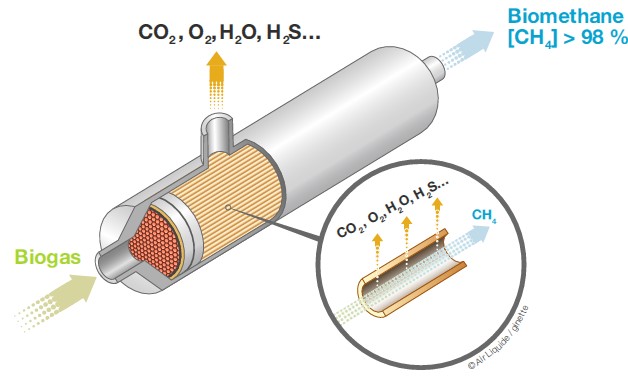

The biogas produced in the digester is a mix of methane, carbon dioxide, water vapour, hydrogen sulphide and more. For this to be useful, it must first be cleaned and upgraded.

Cleaning involves removing the substances which can cause corrosion and/or those unsuitable for the natural gas grid. For example, by adding amounts of oxygen to our system and using sophisticated carbon filters our system, we can reduce harmful hydrogen sulphide from 400 parts per million to 10-40 ppm.

Dutch manufacturer DMT has developed a membrane system that does just that, separating the carbon dioxide from the methane. Because the CO2 and CH4 molecules are different sizes, the membrane system acts like a sieve, allowing them to be separated.

This separation system has massive advantages compared to traditional methods of removing CO2. Its low cost, high energy efficiency, easy operation, modular construction and flexibility all add up to a more efficient and sustainable approach.

The CO2 from the membrane is 98.7% pure – pretty good, but not a high enough standard for the food industry. We start the cleaning process by compressing the gas up to 17 bars. For comparison, pressure inside the tyres of passenger cars is typically 2 – 2.2 bar.

The CO2 is ‘dried’, turned into liquid, re-boiled and turned back into liquid again. Each process helps to remove further impurities. moving gases that can be condensed into liquid.

Liquid CO2 at -43 degrees centigrade is passed into our storage tanks, with a total capacity of 150 m3.

The final stage is to check the quality of the CO2 once certified, the CO2 is collected and distributed.

Two Sides of CO2

Most people are aware that rising levels of carbon dioxide in the atmosphere are the principal driver of climate change.

So it’s ironic that the same substance, used commercially, is a vital part of our fight against climate change. Carbon dioxide is used in the packaging of various foods, including salads and meat, reducing bacterial growth and extending shelf life. As dry ice, CO2 used as a refrigerant, keeping food fresher during transport. Taken together, both processes reduce food wastage, which is a significant contributor to greenhouse gases.

Most commercial CO2 is obtained as a waste product from industrial processes which require substantial amounts of energy. This was evident during the CO2 shortages of September 2021, where two major UK CO2 suppliers were forced to close due to increases in natural gas prices.

There’s obviously a need for commercial carbon dioxide produced by more sustainable means. And that’s exactly what Apsley Farms has been doing since 2016, by providing sustainable CO2 for the food industry.

The Future Is Now

At the moment, commercial CO2 production is unsustainable: it’s energy intensive and relies heavily on industries with huge carbon footprints. There are, however, signs of change, with more and more CO2 being produced from cleaner anaerobic respiration processes.

Apsley is delighted to be part of this revolution. Through investment and innovation, we produce low carbon footprint CO2 to help supply the UK’s needs.

All of the CO2 we supply is recovered from our biodigester. Rather than releasing this natural product of anaerobic respiration directly to the atmosphere, we put it to work for the food industry,

What’s more, every step in its production is grounded in sustainable and efficient practice:

Apsley Farms uses advanced farming techniques to reduce tillage, which in turn reduces CO2 release during the growing of crops for our biodigesters.

Storage and transport of crops – including at our partner farms – is optimised for maximum efficiency, again lowering the carbon footprint of the raw materials.

CO2 is produced through fermentation, an inherently low-energy process This requires a fraction of the energy input of alternative methods, such as the industrial production of ammonia.

Our relatively small energy requirements for CO2 production are met from our own fermentation processes. This is a green and highly efficient way of powering our operations.